Show full size in format and variety of materials

ARISTO cutting solutions for Graphic, Design and Sign Making

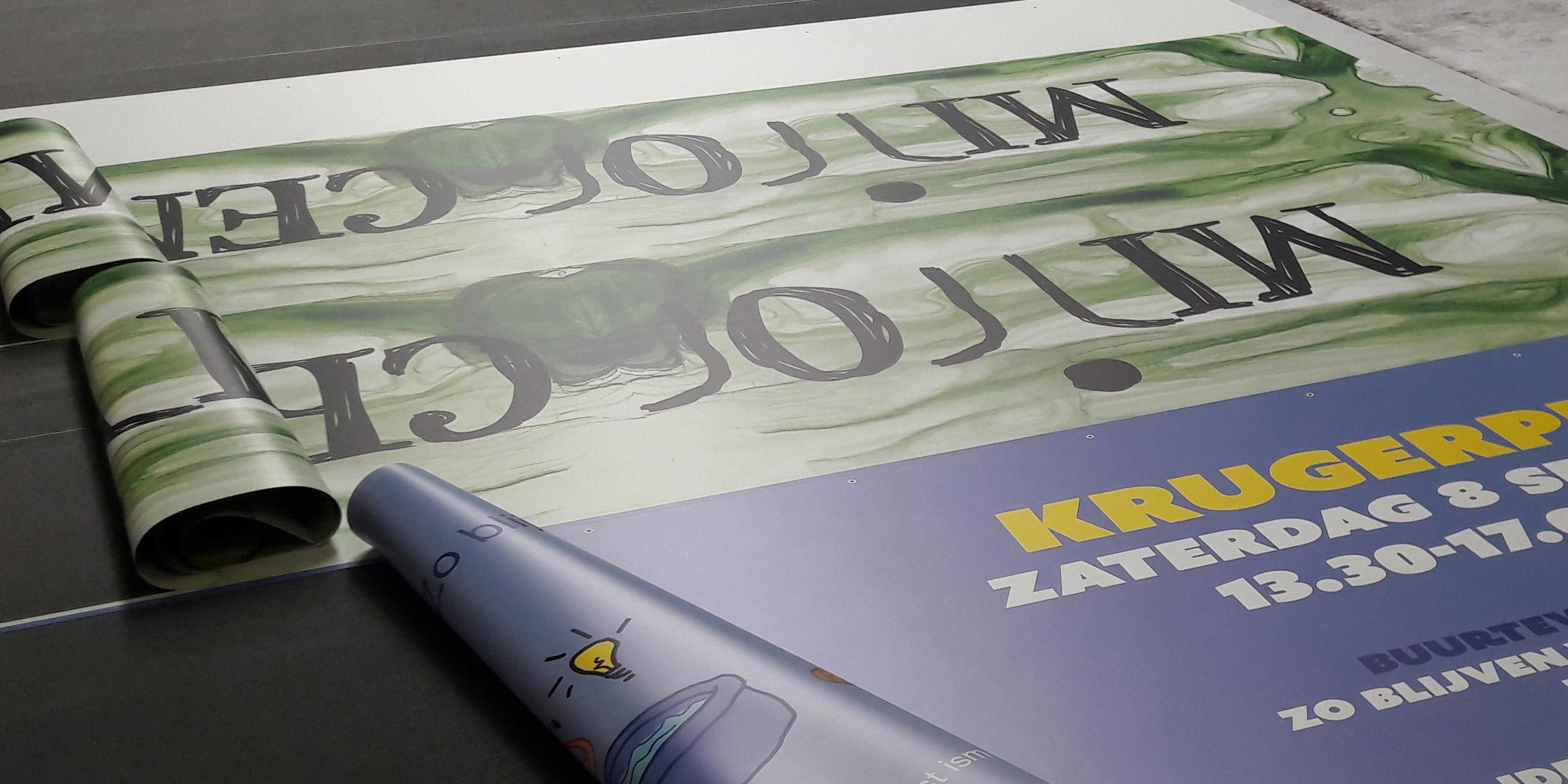

From plexiglass milling to cutting large format prints

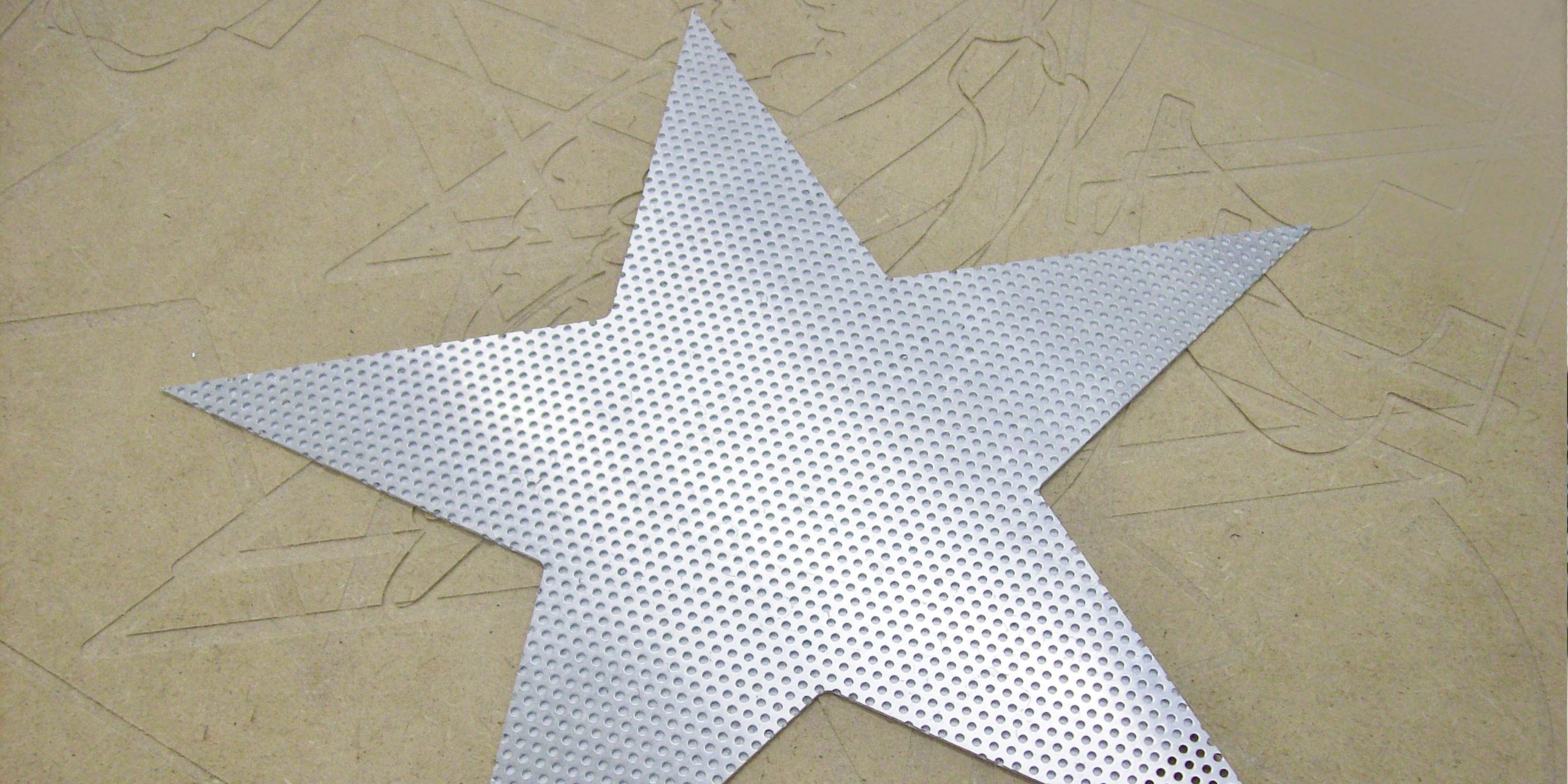

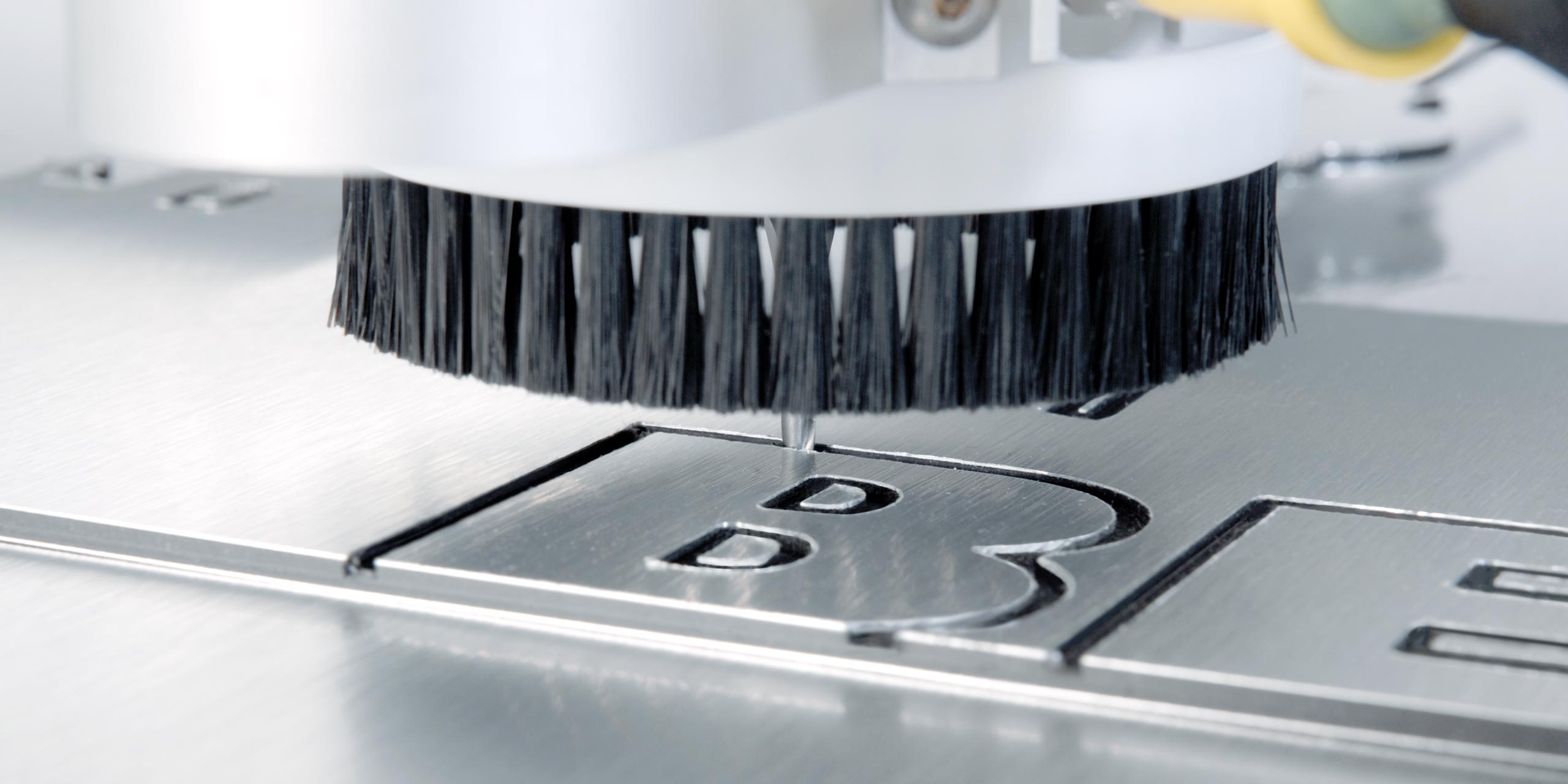

With a cutting width of up to 5,200 mm, maximum precision and pioneering technology in automation, ARISTO cutting solutions are predestined for high-quality cutting projects in digital printing and screen printing. For applications in the field of Sign Making, thicker materials such as aluminum, wood and acrylic can also be milled quickly and cleanly.

The ARISTO® cutter also plays an important role in the flexographic printing sector for cutting printing and coating blankets with high precision, exact cutting quality, the best edge quality, constant cutting depth and no damage to the carrier material.

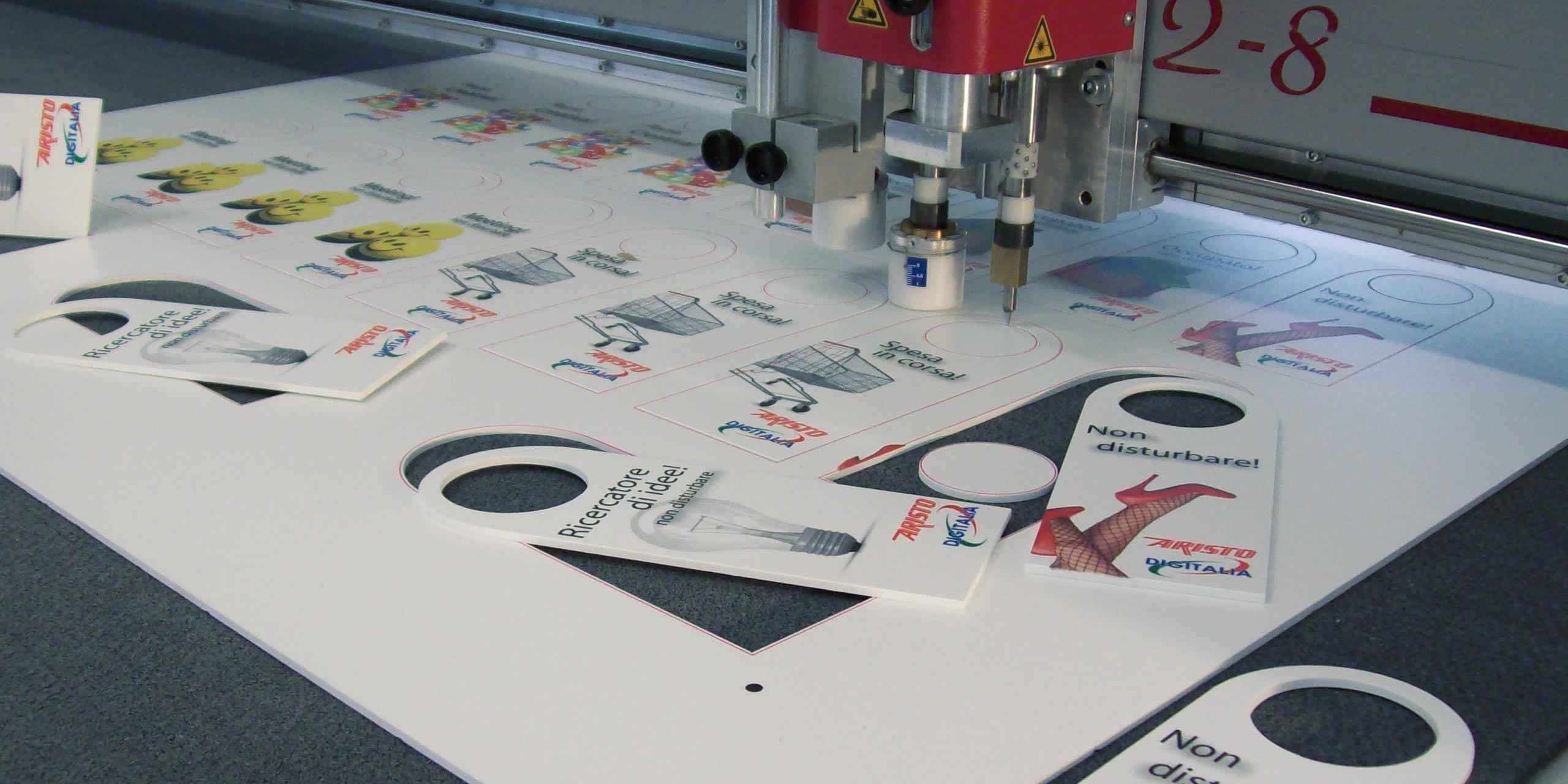

Swapping your application from Routing ridged materials to cutting fabrics and banners or Sticker cutting? – No challenge for the ARISTO®. Your machine selects the right tool head for all the various ways to cut a product. The software CutRecall saves all required values and allows a change of operators without losing any knowledge of How To Cut …

ARISTO® cutters allow you to cut (Kiss Cut) or cut through (Die Cut) a huge variety of materials. Whether sheeted or on a roll – our automatic material feed always ensures that the cut is continued precisely. Our AutomaticEye camera system checks the material distortion of the print and corrects the cut exactly to the desired contour.

Thanks to the adapted tool heads, laminates, heavy foils or special materials such as diamond grade reflective foils can also be processed easily and with high precision.

To optimally automate your work processes, we also offering all machines with conveyor belts, material feed as well as winding and unwinding systems. Our modern loading systems also guarantee the optimal feeding of textile materials in the market of soft signage.

At a glance: Our flatbed cutters can process various materials (extract)

Limitless choice of materials

Whatever material you want to process, our flatbed cutters cut all common materials in the graphic, signage & design industry cleanly, with sharp edges and quickly. Whether soft signage, printing blankets and varnishing blankets for flexo printing or traffic sign cutting.

The ARISTO® BasisRouter also allows you to precisely mill aluminum, non-ferrous metals, wood, hardboard, acrylic, plastics, hard foam panels.

Examples of applications in the Graphic industry

The ARISTO® are as diverse as the Graphic Industry

All conceivable materials can be processed with our various tool heads with just one click. Sheets made of acrylic, Alucubond or cardboard can be processed in contour, as can all banners or flag materials from the soft signage application.

ARISTO® XLR

Various configurations available:

Standard (Basic Maschine)

for roll material (with conveyor)

for plate materials (with conveyor and unloading table)

Tool Heads: MultiHead, HF Router, BevelCutDevice, etc.

ARISTO® LFC

Various configurations available:

Standard (Basic Maschine)

for roll material (with conveyor)

for plate materials (with conveyor and unloading table)

ARISTO® GL

Various configurations available:

Standard (Basic Maschine)

for roll material (with conveyor)

for plate materials (with conveyor and unloading table)

ARISTO® TL

Various configurations available:

Standard (Basic Maschine)

for roll material (with conveyor)

for plate materials (with conveyor and unloading table)

Thought out in every detail

Strong and secured fixation through matrix vacuum zones

The material is securely fixed without a mechanical clamping device. The integrated vacuum system only fixes it in the corresponding zone. Important for your TCO, it significantly reduces energy consumption.

Clear edges with a V-notch-cutter

All required tools are mounted at the same time, no tool head change during the job. Straight and curved cutting lines, HighSpeedCutting, different Bevel Angels, … ARISTO offers an outstanding unique solution.

Time savings through optimized workflow

The ARISTO software, tried and tested thousands of times, ensures a smooth workflow and greater efficiency. The cutting data are taken directly from the CAD system.

Tool Heads

Customized for you!

ARISTO provides you with the optimal solution for your cutting problem, not just a machine. We advise you individually and configure a production line that is precisely fitting to your requirements. Depending on your industry, the processed material, the processing processes and the workflow level. With our comprehensive consulting expertise, we are not only enabling trouble-free production, but also open up new markets and opportunities for you – true to our slogan „Forming your business“.