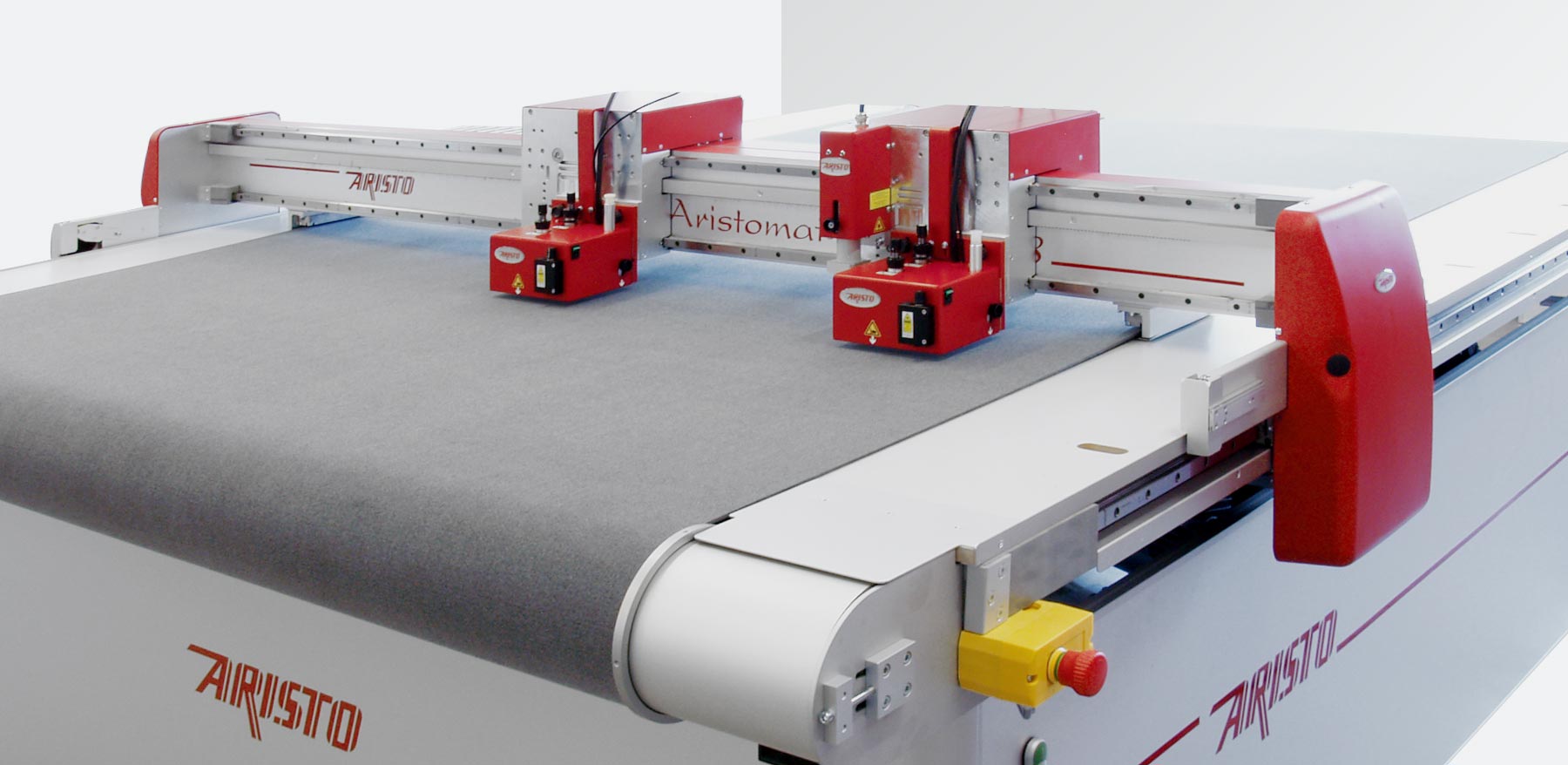

Options for flatbed cutters

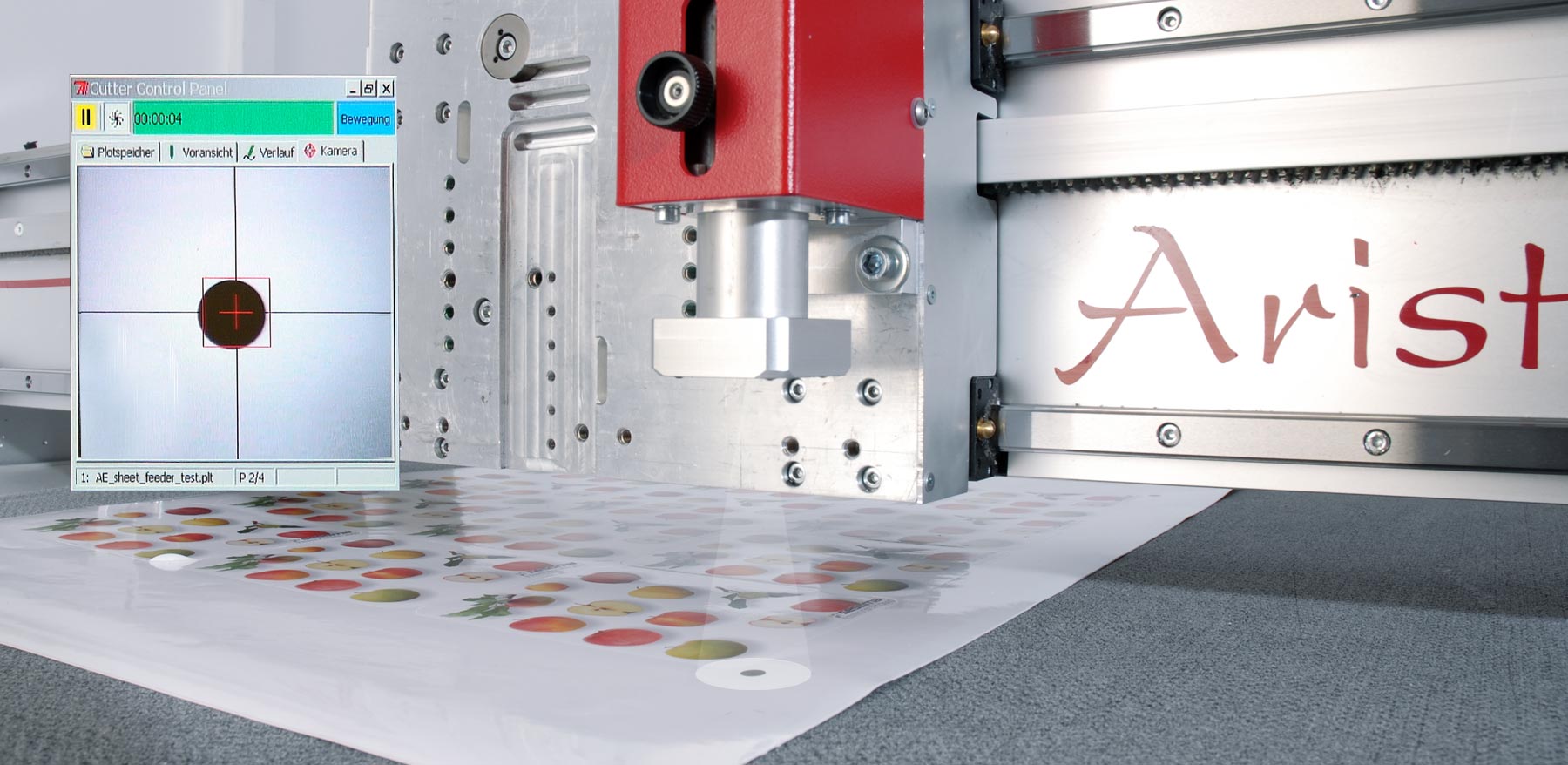

AutomaticEye System

The intelligent camera system enables quick and exact cutting of printed patterns. For that purpose the system first identifies the reference marks through the camera, which is integrated in the MultiHead or available as a stand-alone tool. Compensation values are calculatetd fully automatically for material not right angled to the table top, print distortion or material changes and so guarantees an exact cutting of the contour.

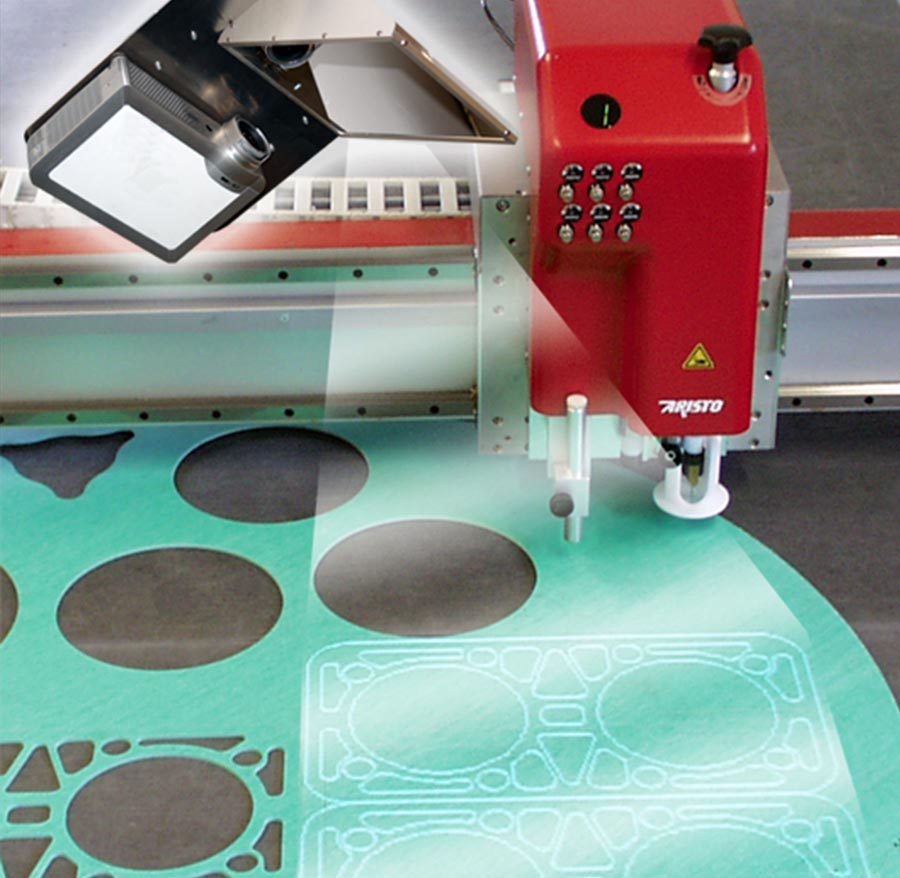

Projection System

The cutting contours are projected onto the cutting surface of the ARISTO®. Thereby, an optimal utilisation of material and the processing of remnants becomes much easier. For the cutting or visually checking of irregularly shaped material, the projection system considerably reduces the amount of work.

- Projection of the contour on the ARISTO® true to scale

- Best possible material utilisation, especially for remnants

- Less waste due to optimal placement of the contour

- Available for ARISTO® series GL, TL and LFC

Material Transport

Unwinding system UW

up to 500 kg

- Roll weight up to 500 kg

- Roll diameter up to 1000 mm

- Available for ARISTO® series GL, TL and LFC

Unwinding system UW up to 1.5 t

- Roll weight up to 1.5 t

- Roll diameter up to 1000 mm

- Available for ARISTO® series GL, TL and LFC

Motorized Wind and Unwinding Device

- Roll weight up to 120 kg

- Roll diameter up to 500 mm

- Available for ARISTO® series TL, GL and LFC

UnrollBowl

- Roll weight up to 90 kg

- Roll diameter up to 300 mm

- Available for ARISTO® series TL and GL

Motorized Winding trough

- Roll weight up to 90 kg

- Roll diameter up to 310 mm

- Available for ARISTO® series SL and TL

RollerBlock

- Roll weight up to 100 kg/m

- Roll diameter up to 350 mm

- Available for ARISTO® series TL, GL and LFC

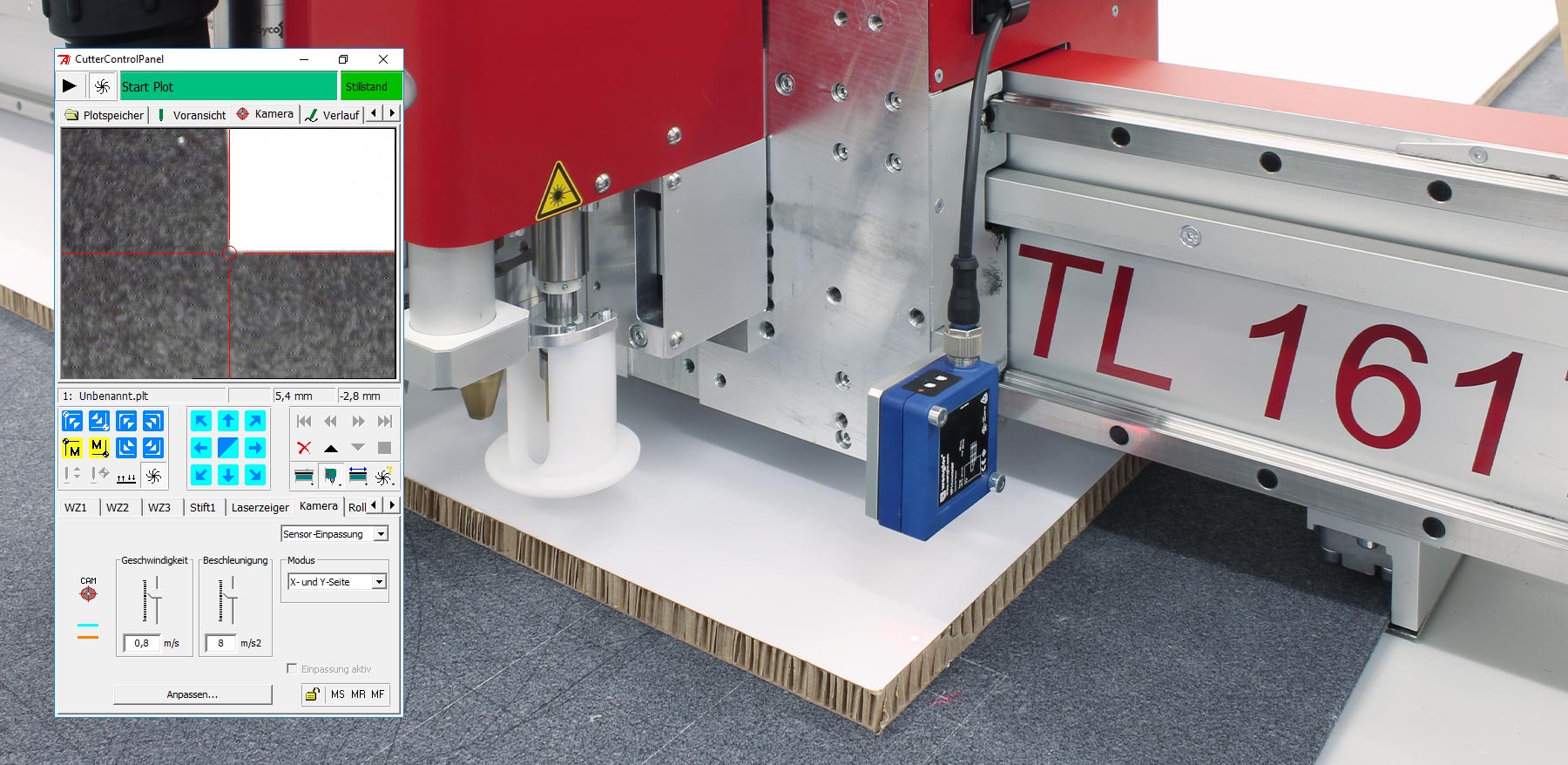

Material Registration

Material Position Detection

With the Material Position Detection a misalignment of the material can be determined and compensated. For this purpose, up to four material edges are scanned at several positions in X- and/or Y-direction with a contrast or reflex edge sensor. This is especially important when a contour is to be cut exactly at one certain position.

CutRecall

Know-how memory for cutting processes

The know-how data base CutRecall consistently increases the performance of the ARISTO® Cutter. New work processes can be set up more quickly and the efficiency increased. With CutRecall the complex material and process specific parameter settings are saved and retrieval for a further work process takes place as fast as lighting.

- dialog-controlled data backup after a process run

- reducing of setup times

- fast data retrieval by mouse-click

- avoid input errors

Productivity

AlternationModeWorkArea

- Loading and unloading parallel to the production process

- Increase productivity by reducing idle time

- For all ARISTO® LFC available

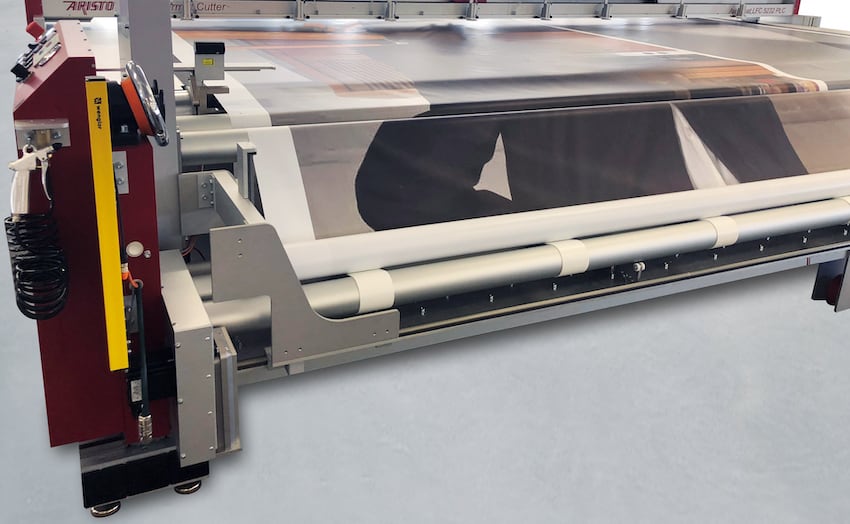

ProductionLineCutter (PLC)

- Remove cut material whilst further parts are being cut

- Placing and/or removing boards

- Circulating conveyor belt

- Available for ARISTO® series GL, TL and LFC

PU Conveyor

- The smooth surface is particularly suitable for fibrous materials such as glass and carbon fiber

- The materials can be removed easily from the conveyor belt

Cutter Software

All common Work Software with HPGL-output can be used for creating and optimizing cut-files for the ARISTO® (e.g. SAi Flexi, Engview, cncCut, AutoCAD, PEAKTOURe, PROCUT, Optiscout, … and many more …). All major print-software supports ARISTO as well.

ARISTO Designer – Packaging & Display Software

ARISTO Package & Display Designer is 2D and 3D software specially developed to improve the packaging and the POP/POS displays production. It is compatible with Adobe® Illustrator® and supports the entire workflow, from the concept design and 3D assembly to artwork arrangement and generation of plotter files.

Features

- Smart Drafting with parametric components

- 3D modelling with realistic 3D PDF generation

- Support of ECMA, FEFCO and Xanita codes

- Library of Packaging Designs

- Library of Display Designs

- Layout and Nesting Optimization

- Adobe Illustrator plug-in

- CAM

The software is available for the packaging sector as well as for the display sector or as a bundle. For more information see www.engview.com →

cncCUT for the construction of gaskets

Thanks to extensive CAD functionality and intuitive user guidance, cncCUT is particularly suitable for creating data for cutting seals.

Very easily and without any prior knowledge, you can quickly create drawings yourself with the integrated CAD system IBECad or load macros and DXF drawings into the software. The drawings automatically receive technology data from cncCUT. The software suggests optimized travel and minimizes idle travel. Each setting in the program can be edited manually if required.

For material optimization, the modules Contour Nesting and Parquet Boxing are also offered. Plotter applications have special functions available:

- response of various tools, e.g. marking pen, oscillating knife, puncher and fixed knife

- automatic tool change

- Supernatant, overcut

- Sort order by tool

- Speeds for each knife according to material and thickness

- Automatic or manual adjustment of the tools according to contour

For more information see www.ibe-software.de →

PEAKTOURe

PEAKTOURe is the innovative and powerful software solution for creating and managing production orders, nesting and efficient and material-saving cutting.

Range of functions:

- Import of ASTM/DXF/HPGL data formats

- Order management

- Material registration

- Automatically and manually nesting

- Online and offline nesting

- Control of the cutting tables

- Sorting aid

- Interfaces to and from ERP systems

- Process-controlled production processes

- Production monitoring statistics

For more information see www.rg-technologies.de →

PROCUT®

PROCUT® is a software solution for the nesting (overhead-light projection) and the cutting of patterns by means of die-less cutting technologies (knive, laser, waterjet). The system can be operated either as a stand-alone solution (at the respective cutting table) or integrated in an IT-network (as work preparation). The data for cutting is generated by the CAD-system automatically.

Features:

- data import

- automatic layout / nesting (leather)

- modifications of patterns

- bar code support

For more information see www.procam-software.com →

SAI Flexi - Ideal Tool for Data Optimization

The FlexiSign family is considered the world’s leading professional software solution for design and production in signmaking, advertising technology, large format digital printing, screen printing and the CNC industry.

In addition to the extensive functionality and sophisticated vector editing tools, the modules of the FlexiSign family are particularly characterized by the large number of pre-processors. Data of many different formats can be imported and optimized for output to the ARISTOMAT cutters.

Functions:

- Animated cutting preview

- Tool for job release

- Cutting contours with third-party RIP

- Data Matrix Code

- Visual cutting order

- QR Code

- Tool for rhinestone filling

- TrueShapeNesting

For more information, please visit www.thinksai.com →

OptiScout Production

Modular optical recognition software system for multifunctional flatbed machines for industrial usage. Finishing software for outline-exact cutting with or without camera-controlled orientation.

Key Benefits:

- Supports industrial automatized workflows

- Minimizes share of rejects because of

- optical recognition system

- print divergency compensation

- High-End lens/Camera combination allows

- Usage of miscellaneous video marks

- High speed mark recognition

- In most cases no additional illumination needed

For more information, please visit www.optiscout.com →