ARISTO Cutting Solutions

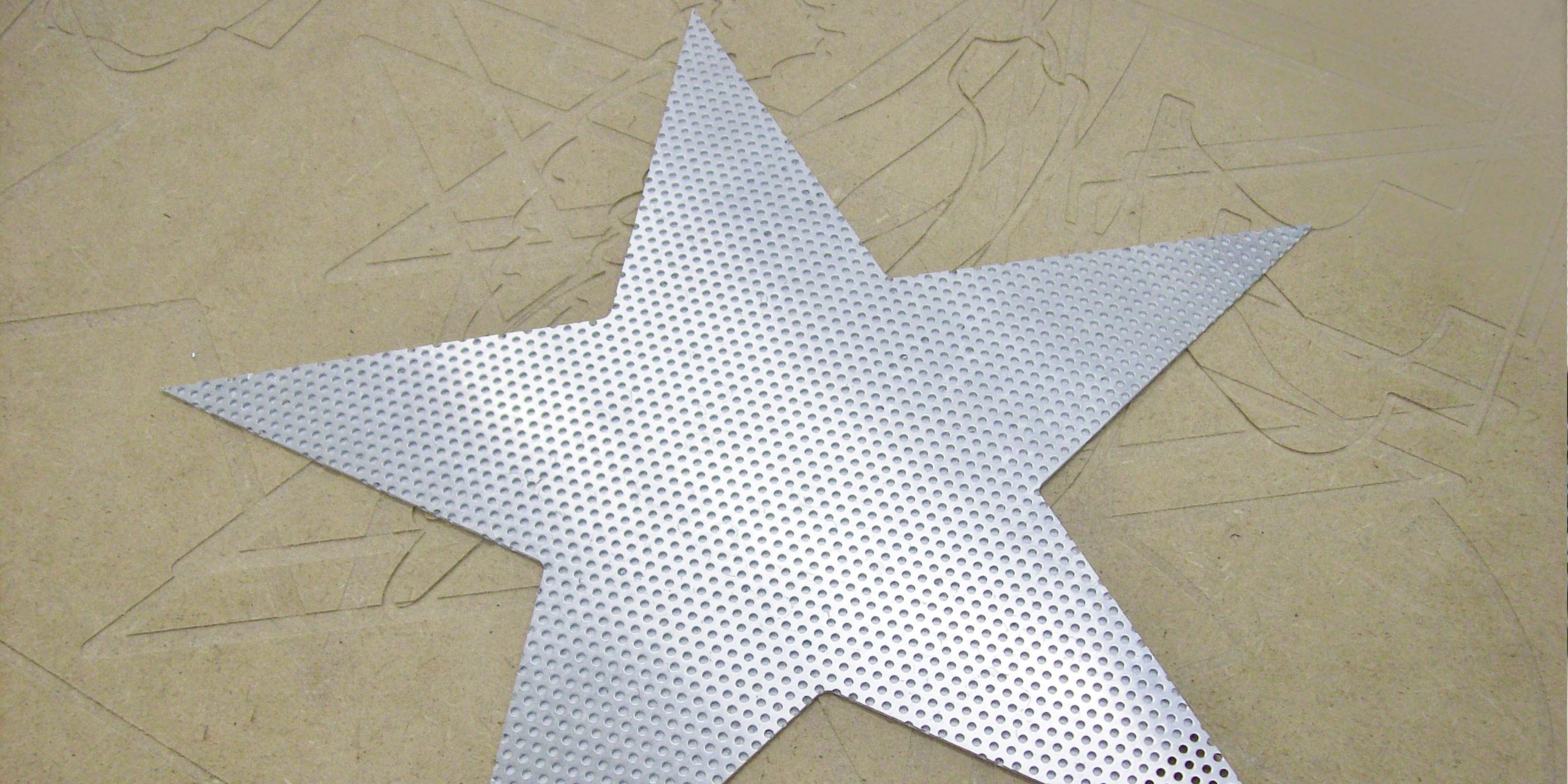

As the leading German manufacturer of large-format, computer-controlled flatbed cutters for CAD / CAM processing of stiff or pliable materials, we solve the world’s most demanding cutting tasks precisely and reliably. The numerous application-specific tool systems of our ARISTO® cutters enable high-quality die- or kiss-cutting, creasing, scoring, punching, milling or labeling a variety of materials – fixed or oscillating.

ARISTO® TL

Work area 1300 – 1900 mm

Product sheet (PDF) →

ARISTO® XLR

Work area 2200 mm

Product sheet (PDF) →

Tool Heads

Accessories for tool heads

Click here for PDF download →

please order by e-mail sales@aristo.de

Doing better economically!

With ARISTO® flatbed cutters you produce far more economically than with available alternative solutions. Because the high output and the optimal material usage of our machines pay off in a short time. In the long term, you benefit from their robust technology through constant quality and precision, as well as the lowest maintenance effort.

A from all sides freely accessible work surface and extremely robust traverse bridge with minimal protruding at the sides. Powerful AC-servomotors and the modern CAN-Bus-steering technique enable the high throughput. Whether cutting, creasing, perforating, milling, marking, engraving or sealing, ARISTO offers a solution for every process.

Low operating costs, always upgradable for new applications

- Robust construction with low maintenance

- Electromechanical oscillation drive

- Energy saving vacuum system

High profitability

- Maximum flexibility in use

- Outstanding processing speed

- Suitable for single piece production or series production

- Various use of materials

Qualified service support

- Great availability of the ARISTO service specialists

- Customer support all over the world

- Own production and storage of spare parts

News

Precision is in our DNA

Founded in 1862 as a factory for mathematical and measurement equipment, ARISTO has stood always for the highest precision and reliability from the very beginning. After developing slide rulers, drawing equipment and pioneering work in geometric data processing, ARISTO has been successful on the market with the ARISTO® flatbed cutters since 1959. State-of-the-art CNC cutters have made ARISTO the leading German manufacturer of large-format, computer-controlled flatbed cutting machines.

Our wealth of technical ideas has been awarded several times with the innovation prize of the Free and Hanseatic City of Hamburg. With our own national and international patents and decades of experience, our machines continue to develop and manufacture in ours. With this way we can ensure the precision, reliability and high performance that you expect from ARISTO machines. Our sales and service centers around the world ensure optimal support.