Industrial cutting with all technical freedom

ARISTO cutting solutions for production cutting

Processing composites, textiles and leather exactly according to your ideas

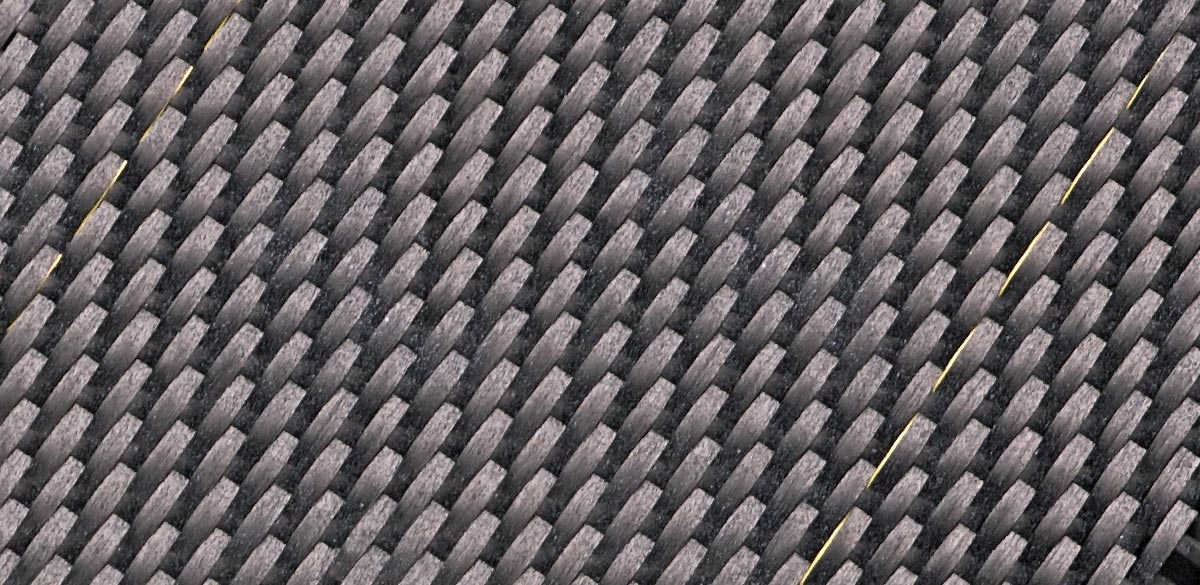

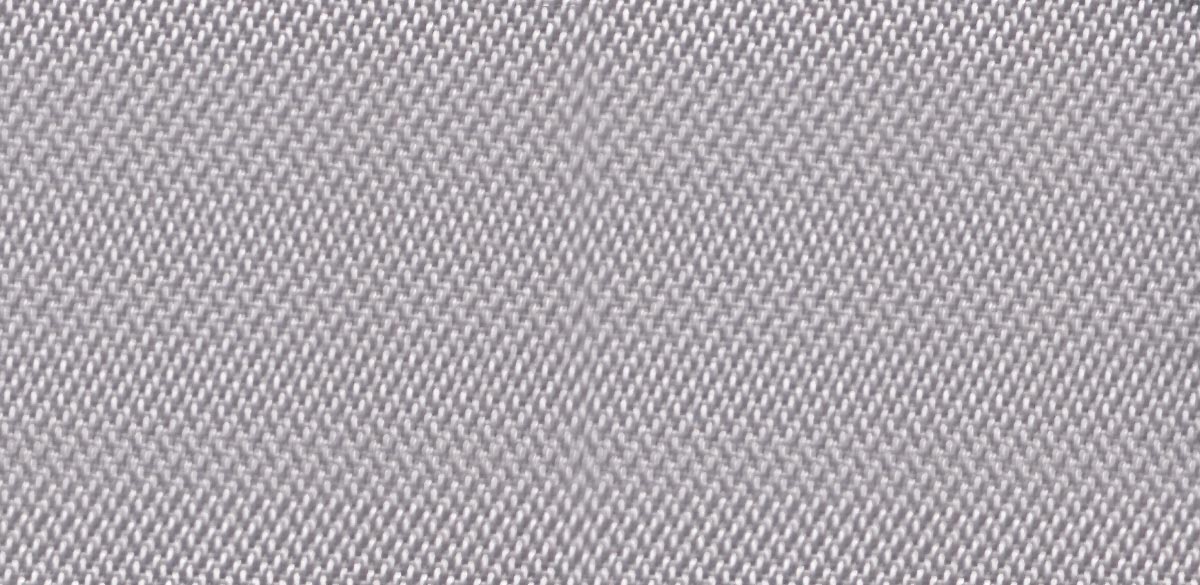

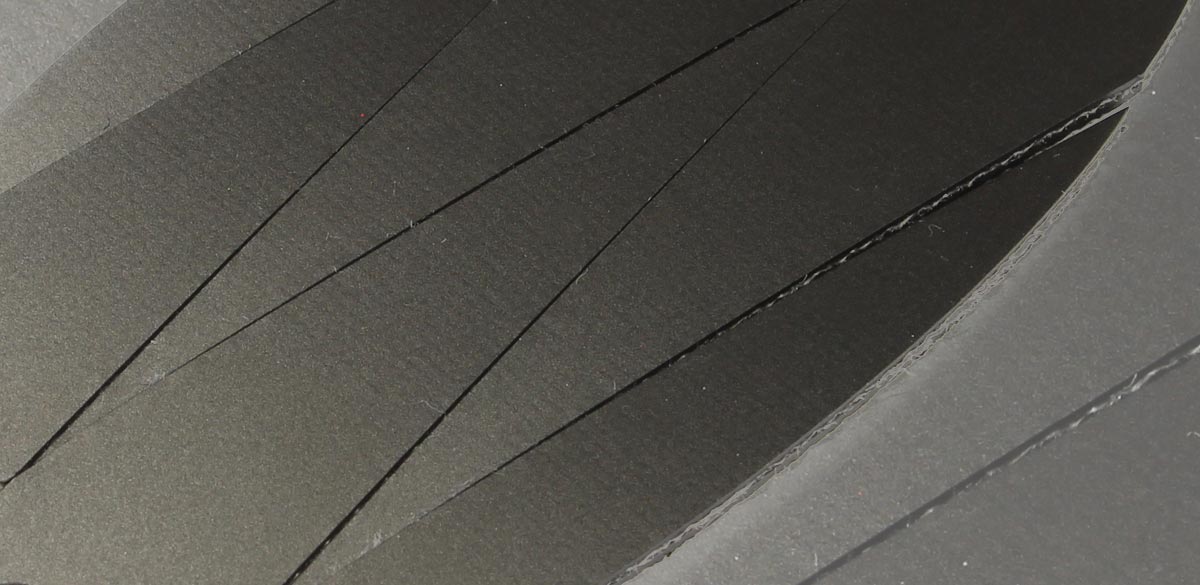

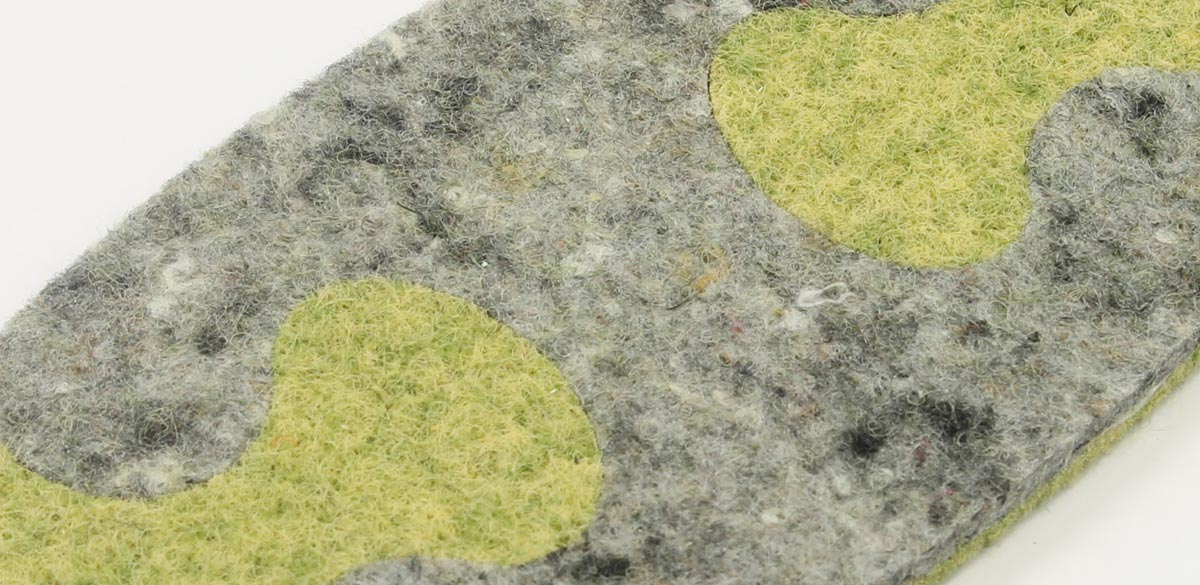

Due to their suitability for cutting composite semi-finished products in a wide variety of designs and fabric structures, ARISTO® cutters are increasingly being used in research, production and development.

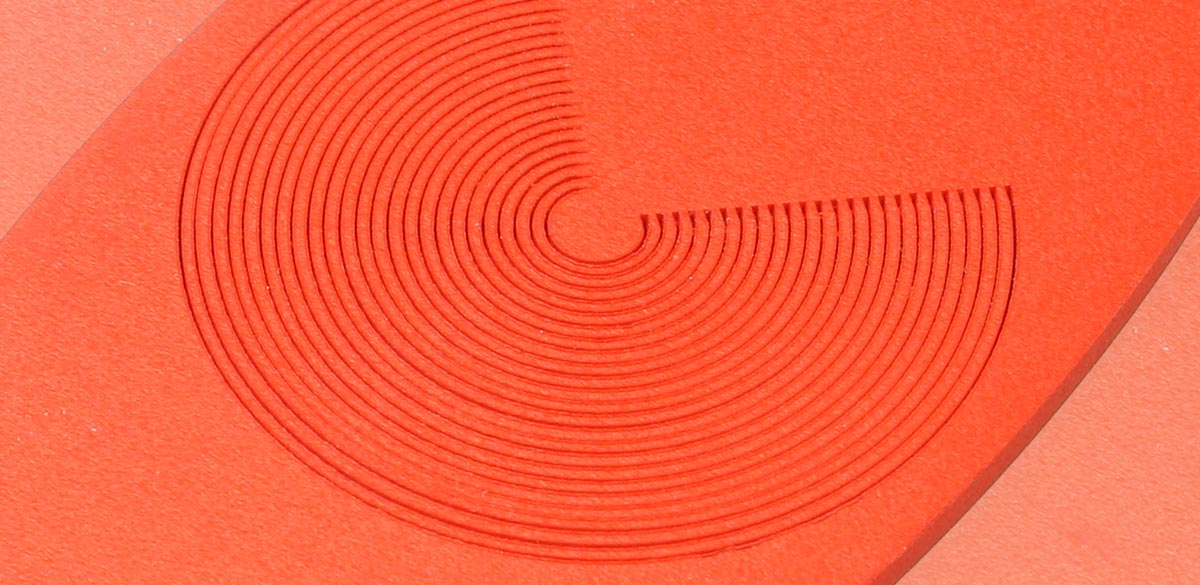

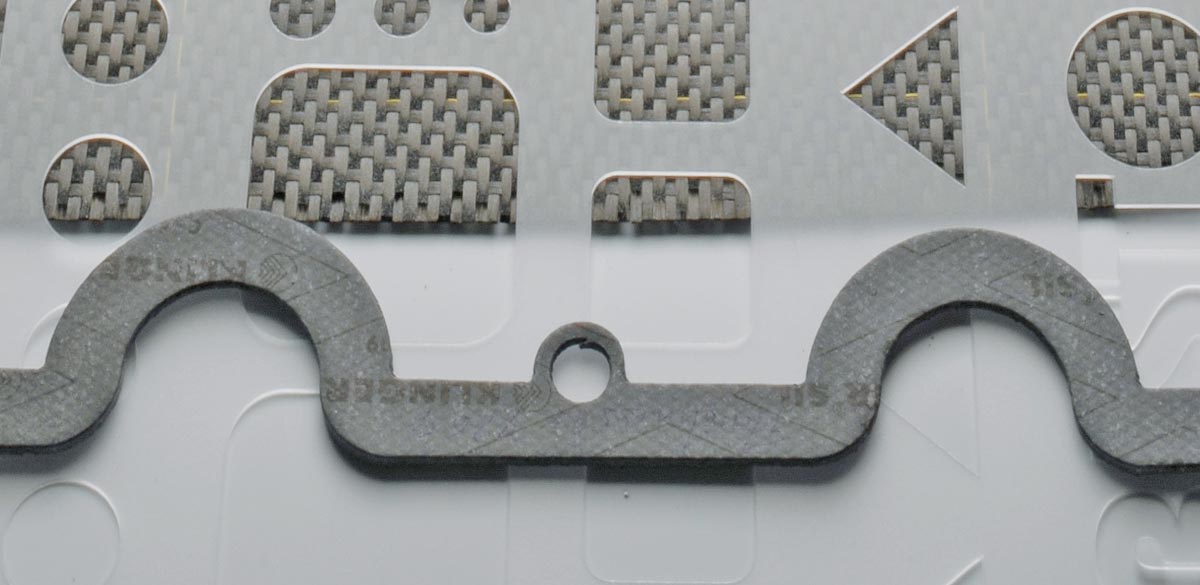

Overview: Our flatbed cutters can process various materials (extract)

All materials can be processed

Examples in the area of production cutting

Molded according to your requirements

Whether in the automotive or medical industry, in aviation – there is hardly any area in which our cutters cannot be used. There are no limits to the variety. Just as little as the universally applicable flatbed cutters from ARISTO®.

ARISTO® TL

Various configurations available:

Standard (Basic Maschine)

for roll material (with conveyor)

for plate materials (with conveyor and unloading table)

ARISTO® GL

Various configurations available:

Standard (Basic Maschine)

for roll material (with conveyor)

for plate materials (with conveyor and unloading table)

ARISTO® LFC

Various configurations available:

Standard (Basic Maschine)

for roll material (with conveyor)

for plate materials (with conveyor and unloading table)

ARISTO® XLR

Various configurations available:

Standard (Basic Maschine)

for roll material (with conveyor)

for plate materials (with conveyor and unloading table)

Tool Heads: MultiHead, HF Router, BevelCutDevice, etc.

Thought out in every detail

Strong and secured fixation through matrix vacuum zones

The material is securely fixed without a mechanical clamping device. The integrated vacuum system only fixes it in the corresponding zone. Important for your TCO, it significantly reduces energy consumption.

Clear edges with a V-notch-cutter

All required tools are mounted at the same time, no tool head change during the job. Straight and curved cutting lines, HighSpeedCutting, different Bevel Angels, … ARISTO offers an outstanding unique solution.

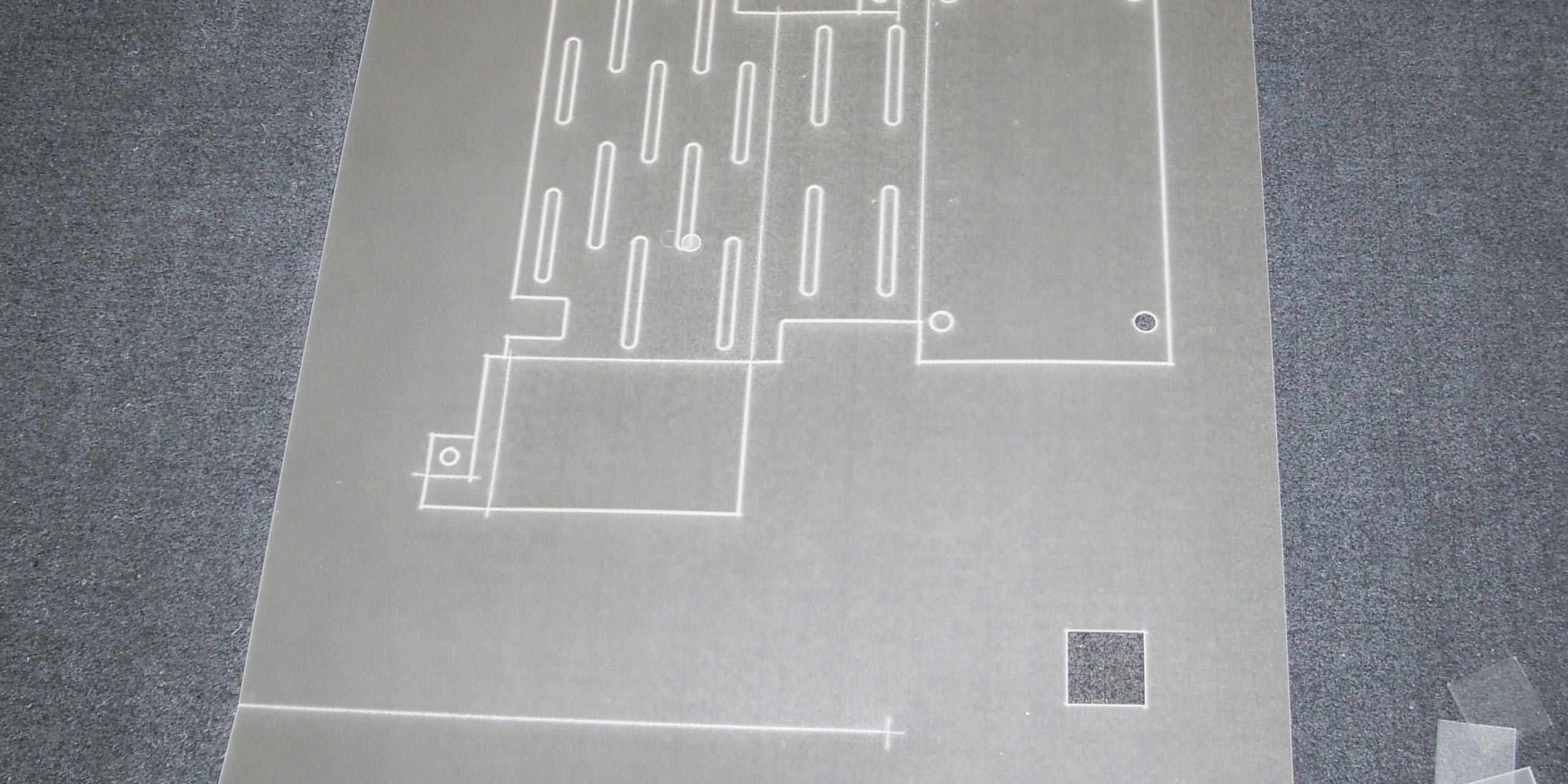

Time savings through optimized workflow

The ARISTO software, tried and tested thousands of times, ensures a smooth workflow and greater efficiency. The cutting data are taken directly from the CAD system.